For a vibrational stress with constant amplitudes, this dependence is represented by the fatigue strength line, the inclined part of the Wöhler line. The complete Wöhler line extends from the tensile strength via the fatigue strength line to the fatigue limit.

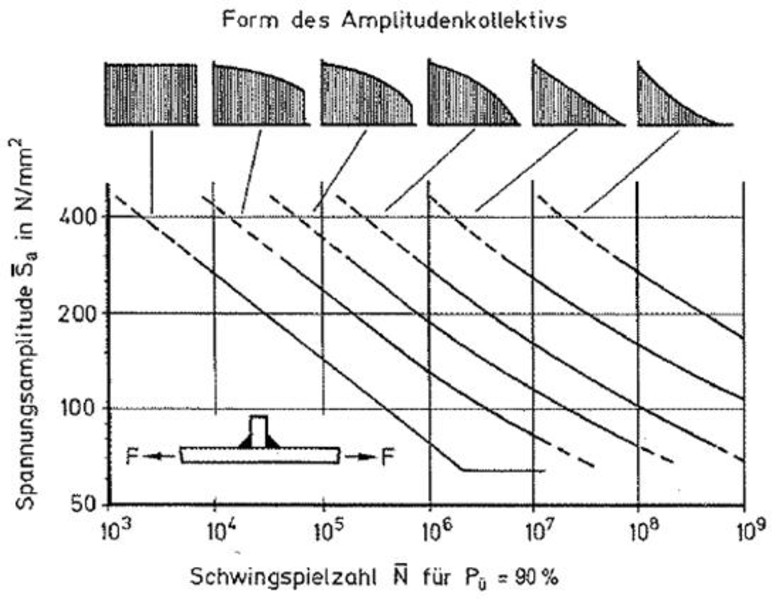

Important: If the oscilation stress on with constant amplitudes but with the same maximum value as in case (c) with a more or less random-like sequence of differently sized amplitudes (d), the tolerable number of cycles will exceed the fatigue limit line. A strain curve of this kind is for the operation of most components, including also be assessed for tower constructions of wind turbines, characteristic and the procedures of operating resistance. With the Gaßner life line it is one of the fatigue limit line corresponding dependence between the stress level and the finite lifetime, expressed in number of cycles.