Cast nodes

Cast nodes

Cast nodes are an important component of Brücken and other load-bearing structures. They consist of a cast steel structure made up of several bars and nodes. This design offers high stability and rigidity combined with low weight. The design and calculation is an important aspect in the planning of supporting structures.

The choice of the appropriate node type and height depends on various factors, such as the tension, the distance between the nodes and the topography of the terrain. The design of cast nodes is an important step in the design of structures as they provide a cost-effective and reliable solution for load bearing capacity. There are many companies that manufacture and offer cast nodes for the construction of bridges and other structures.

The calculation of cast nodes is an important aspect in the planning of load-bearing structures. The calculation involves determining the loads acting on the node and the forces that the node exerts on the surrounding structures. Factors such as temperature, humidity and wind speed must also be taken into account in the calculation.

Alternative to the welded nodes

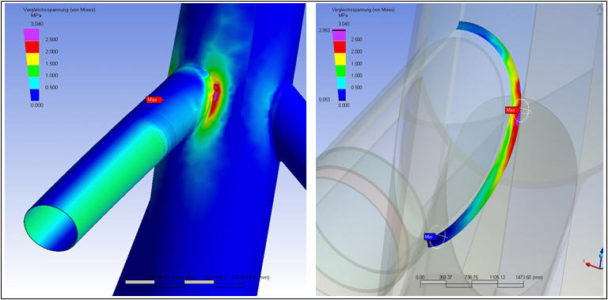

As an alternative to welded pipe nodes, cast nodes can be used for load-bearing and foundation structures of Offshore wind turbines are used. The aim of the dimensioning is to minimise Spannungskonzentrationen through variable fillets in the transition area of the pipes. This enables a reduction in the required sheet thickness compared to welded pipe joints.

In some areas, cast nodes are a cost-effective and reliable solution for the load-bearing capacity of bridges and other load-bearing structures. However, the design and calculation require careful planning and consideration of various factors. It is important to select the correct node and carefully calculate the loads and forces to ensure the stability and rigidity of the structure.

However, production is expensive, so comparative calculations must be used to decide the minimum number at which the production of complex moulds makes economic sense. In addition to the verifications in the ultimate limit state andfatigue strength thermal analyses are usually also required for the casting process in order to be able to assess the development of residual stresses during the cooling phase.

Services

The design requires careful planning and calculation. The choice of the right type of node and the right node height depends on various factors, such as the tension, the distance between the nodes and the topography of the terrain. During construction, it is also important to know the materials and their properties in detail. The choice of the right material is crucial for the stability and rigidity of the node.

The SKI Ingenieurgesellschaft can offer the following services for the design of cast nodes:

- Load simulations in the limit state of load-bearing capacity and serviceability

- Calculations of fatigue loads in the time and frequency domain

- Buckling analyzes

- Evidence for welding and bolt connections

- Local stress and fatigue calculations

- Concept studies for novel node forms

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0