Die Montage auf der Baustelle erfolgt mitttels Kletterbauweise. Die Vorspannung der Betonfertigteile wird über externe Spannkabel realisiert, die entlang der inneren Turmwand verlaufen. Der hochfeste Beton ermöglicht verkürzte Fertigungszeiten und ein Erscheinungsbild in Sichtbetonqualität.

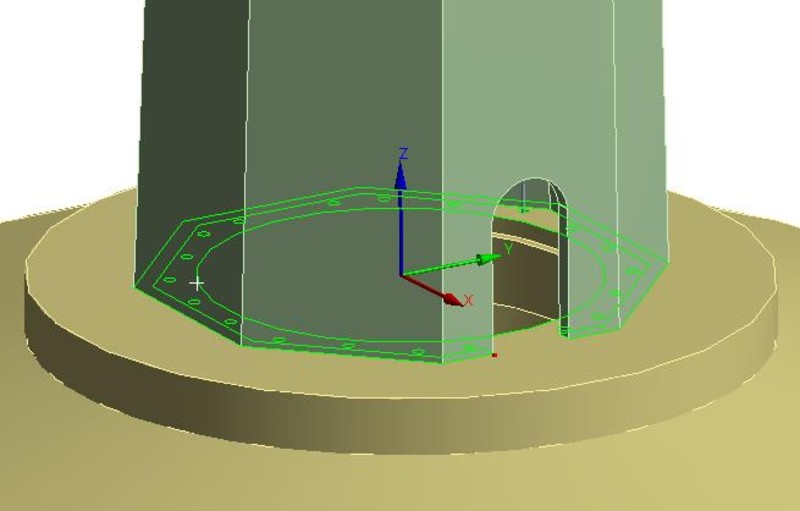

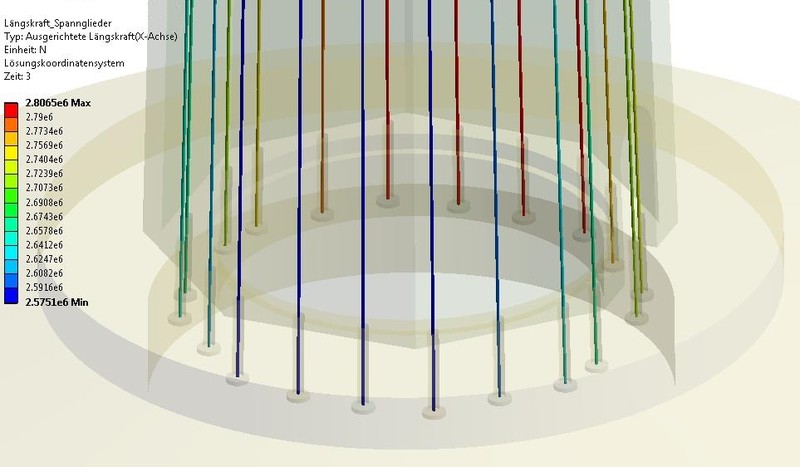

With reference to the figures, the design of the clamping system is illustrated wherein by using a 3D model of each clamping member is checked. The stress changes on the bending pressure and flexural tension side be analyzed in response to the applied bending moment and evaluated in diagram form.