Notch stress concept

Consideration of the local notch effect

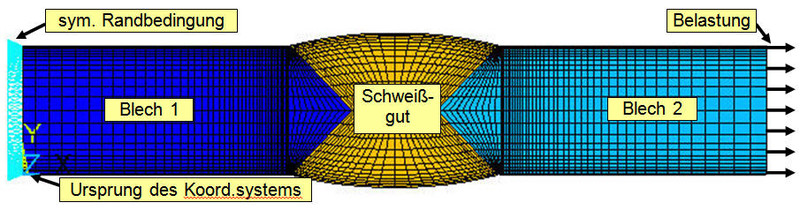

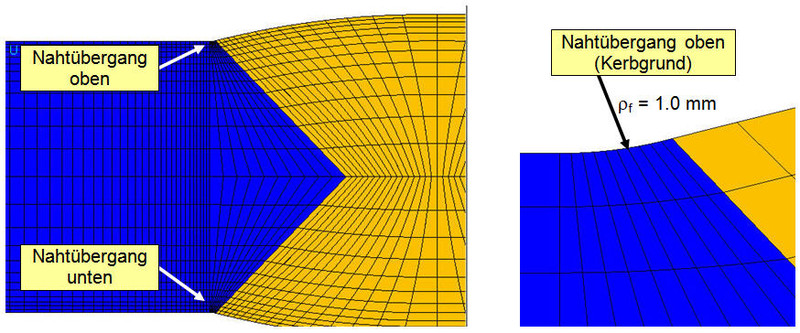

In the Notch Stress Concept (NSC), the elastic stresses locally present in the notch root are used as a basis for the failure-critical crack location to assess the fatigue safety and are compared with locally bearable stresses. In contrast to the nominal stress concept– and structural stress concept, the stress peaks due to the seam geometry are recorded and taken into account by the so-called notch stress on the stress side. The geometry values and the material condition must therefore be completely describable even in the vicinity of the failure critical point. An analytical determination of the notch stresses is generally only possible for simple geometric shapes. As a rule, the notch stresses are determined by means of finite element methods (FEM).

Fictitious notch radius and notch local case class

The beginnings of the notch stress concept go back to RADAJ and refer to fatigue strength, since there are approximately purely elastic stresses in the notch root. The real radius of the notch is rounded off fictitiously depending on the material and the strength hypothesis, since local stresses in the notch base do not have the full effect on the fatigue strength (micro support effect). The stresses determined with this fictitious radius are then directly compared to the fatigue strength of the base material. The generalization in the fatigue strength range was carried out by SEEGER by transferring the characteristic values and functions of the nominal stress concept to the notch stress concept. The calculated notch stresses are compared to notch stress WÖHLER lines. Existing scatters, e.g. in a weld seam due to seam geometry, roughness, seam defects, residual stresses and material strengths are included in the WÖHLER lines. As a recommendation, a characteristic resistance value of 225 MPa (FAT225) is given for this notch stress WÖHLER line by IIW.

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0