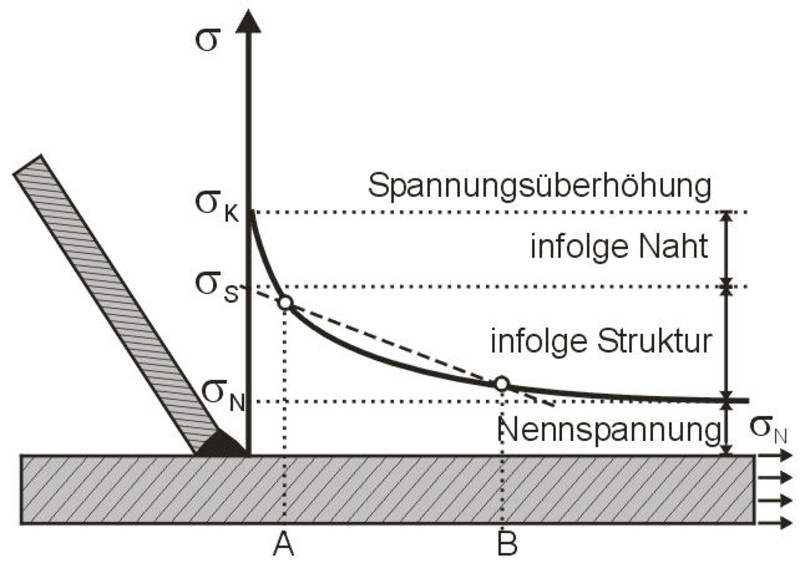

The determination of the structural stress sS is done by measurement or calculation of stresses at specified intervals to the base point of the weld, the weld to the base point then be extrapolated linear or quadratic. Structure in the fictitious stress increases are included in the geometry of the structure (structural discontinuities). However, local stress effects due to the weld geometry are not recognized.

Structural stress concept

The structural stress concept for hot spots

The Structural Stress Concept (SSC) is an extension of the nominal stress concept. It is used for complex geometric shapes where the nominal stresses can no longer be determined according to the elementary strength theory. The structural stress concept, which is based on an approach according to HAIBACH, proves to be particularly advantageous for welded hollow profile constructions. It calculates the stress increases due to the component structure at the weld root by determining a fictitious structural stress at the critical point (also called hot-spot).

The right figure shows the definition of the structural stress in comparison to the nominal stress and the local notch stress using the example of a strut connection. A Stress Concentration Factor (SCF) as a function of the type of load (axial pressure, bending in the plane, bending out of the plane) is usually specified for the notch detail to be considered in each case. This describes the relationship between structural stress and nominal stress. The fatigue strength is then evaluated by comparing the existing structural stress with structural stress Wöhler lines.

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0