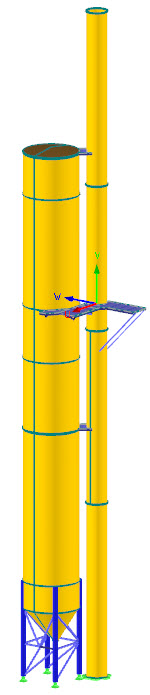

Smokestacks

Smokestacks

In industrial and commercial areas it is necessary to let exhaust fumes from production escape at a sufficient height. This is done by using cooling and waste gas chimneys, which partly exceed the limit of 100m.

There are several variants to choose from, depending on the construction and the chosen material. Until the beginning of the 20th century, mainly brick chimneys were used, which are limited in height for static reasons.

As developments in the field of concrete and installation techniques progress, cooling towers made of reinforced concrete are used, for example, in power plant construction and large industrial plants. These usually have a relatively small wall thickness and are usually erected using the climbing construction method.

Tubular steel towers are used in the chemical industry with acidic or basic exhaust gases. In this case, either a coating of the structural steel prevents rapid corrosion or stainless steels are used as an alternative. The individual steel pipe sections are connected to each other via ring flange connections and fixed anchors in foundation befestigt.

The design of the steel tube sections for chimneys is similar to that of support structures for wind turbines sehr ähnlich. Die Hauptbeanspruchung der Schornsteine stellt dabei der Wind dar. In einigen Fällen kommen noch hohe Temperaturen oder Eisansatz hinzu, welche in der Bemessung berücksichtigt werden müssen. Insbesondere müssen bei diesen schlanken und hohen Bauwerke die windinduzierten Querschwingungen untersucht werden. EIt leads to vortex induced vibrations, when on the opposite sides of a structure alternating vortices peel off. If the excitation by the wind lies in the frequency range of the structure, resonance effects and a swaying of the vibrations can occur at right angles to the wind.

Our services

The SKI Ingenieurges. mbH can be used for the design of new Masts and smokestacks and the conversion of existing constructions to be constructed and the conversion of existing tanks systems:

- Bestandsaufnahme und gutachterliche Beurteilung von bestehenden Konstruktionen bezüglich einer Umnutzung

- Static calculations in the limit states of the Sustainability, servicebility state and Fatigue limit of supporting structures including foundation and anchoring

- Verifiable static calculation for the conversion of supporting structures or extension with extensions (transmission and radio technology) including detailed verifications (e.g. for connections, brackets and platforms)

- Dynamic structure analyzes (natural frequency analysis) for defined excitations (e.g. due to Vortex induced vibrations)

- Determination of the load and verification of the structure in case of earthquake load

- Stress and stability analyzes of constructions in steel or concrete

- Expert reports and remediation concepts in case of damage

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0