Crack growth concept

From scribe to crack through the

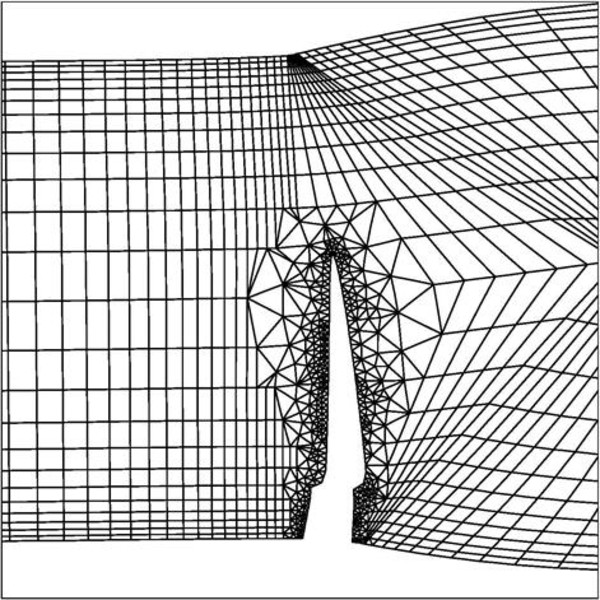

The crack propagation concept (RFK) assumes that crack initiation has already occurred in the component. In this fracture mechanics approach, the crack shape and crack size are assumed to be known, and the service life until crack initiation is generally not taken into account. In contrast to the concepts described above, it is not the crack initiation that is examined here, but rather the crack growth up to a critical crack length at which residual fracture occurs due to the weakening of the cross-section.

Since the stresses at the crack tip can assume very high, theoretically infinite values, local stresses and strains are unsuitable as characteristic stress variables. Instead, the stress intensity factor K, which depends on the crack length and stress level, is used in linear elastic fracture mechanics (LEFM) with negligible small plastic zones at the crack tip. Large plastic crack tip stresses can be captured by elastic-plastic fracture mechanics (EPFM).

The main field of application in steel constructionis less the replacement of stress-based fatigue calculation than the evaluation of cracks and crack-like imperfections. In particular, the crack propagation concept can be used to estimate the remaining service life in order to define the necessary inspection intervals or material toughness to avoid brittle fractures.

One option for the continued operation of structures

Crack propagation in metallic materials is a key area of research in fracture mechanics and plays an important role in the service life estimation of safety-critical components. Crack propagation analysis is also a suitable assessment criterion with regard to the possible continued operation of cyclically stressed structures or the determination of inspection intervals.

Significance in practice

The service life of load-bearing steel components can basically be divided into two sections:

- design life

- crack propagation time

Until now, fatigue-critical components in civil engineering have been designed primarily to withstand a technical crack, i.e. the design life. Components relevant to structural stability are usually assessed mathematically using linear damage accumulation. The crack propagation time allows safety-critical components to be assessed beyond their design life.

For the crack propagation duration, crack propagation is calculated for the so-called technical crack under additional load conditions (static and/or dynamic). In the case of additional cyclic loading, for example, the crack propagation rate describes how quickly a crack grows per load cycle. Crack propagation depends heavily on stress intensity, material behaviour and environmental conditions. In the initial phase, the crack grows steadily with each load cycle. This phase is referred to as stable crack propagation and can be described well using fracture mechanics methods, e.g. the Paris-Erdogan law. Eventually, the crack reaches a criticaal length at which unstable fracture occurs.

SKI Ingenieurges. mbH can perform crack propagation analyses and assess notch details (fatigue-critical components and connections) with regard to residual service life.

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0