- Axial pressure buckling due to axial force and bending

- Circumferential pressure dents due to wind and wave loads

- Extent of shear buckling due to torsion

- Interaction from the above load cases

Tubular steel tower

The tubular steel tower as standard version

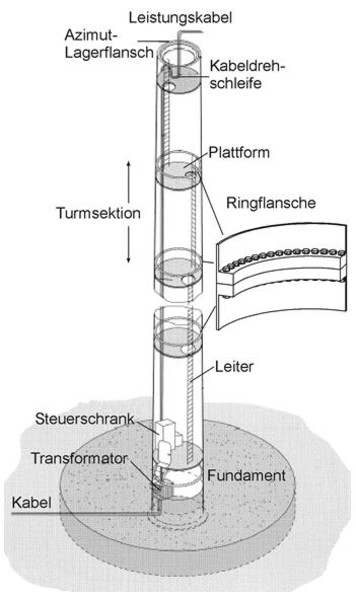

The tubular steel tower consists of several sections, which are either cylindrical or conical in shape (see figure on the right). Each tower section is assembled in production facilities from individual tube sections which are previously cut from heavy plates with flame cutting equipment and formed with round roll bending machines. The length of the individual shots is limited by the dimensions of the bending machine and is usually 3.0 to 3.5m. After the longitudinal seam of all pipe sections has been welded, the first pipe section is welded with a ring flange. The ring flange gives the first tower section its dimensional stability so that further sections can be welded with circumferential seams. For this purpose, the pipe sections are fixed with tack welds and stored on roller stands. The horizontal section can thus rotate around its longitudinal axis. The lengths of the resulting tower sections are mainly determined by the transport capacities and can be up to 35 m.

After welding the complete section, fixing points for the installations in the tower are welded on. This is followed by the corrosion protection of the individual tower sections and the installation of the tower interior equipment. Finally, the tower sections are transported to the construction site with special vehicles, erected there successively with a mobile crane and transported via ring flange connections .

Extent of shear buckling due to torsion tubular steel towers belong to the shell structures due to their geometry and slimness. In this respect, for the towers and the stability against shell buckling must be verified with the following load cases shall be considered:

![csm_RFL_Segementansatz_aa6a633bd5 Ringflanschverbindung [SEIDEL, 2001]](https://ski-consult.de/wp-content/uploads/elementor/thumbs/csm_RFL_Segementansatz_aa6a633bd5-oty2chba4e7ssvru94rp402l4upk1klb56kcudxibk.jpg)

Services

As part of the assessment of steel tower structures for wind turbines following services can be offered:

- Natural frequency analysis

- Load simulations in the ultimate limit state

- Calculations of fatigue loads in the time and frequency domain

- Buckling analyzes for individual pipe sections

- Evidence for welding and bolt connections

- Berechnung for pipe nodes and ring flange connections

- Calculation of wave loads in combination with other effects

- Design of grouted Joints and pile-sleeve connections

- Local stress and fatigue calculations for tubular joints

- Concept studies for novel foundation structures of offshore wind turbines

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0