Reactors

In the chemical industry, a large number of different reactors are used. Especially in the crude oil processing industry. Many everyday objects are made of plastics. These are manufactured using small PET pellets. For storage and further processing, silos for the pellets are needed in this area. On the one hand, these are under high pressure and on the other hand, high operating temperatures are required for processing.

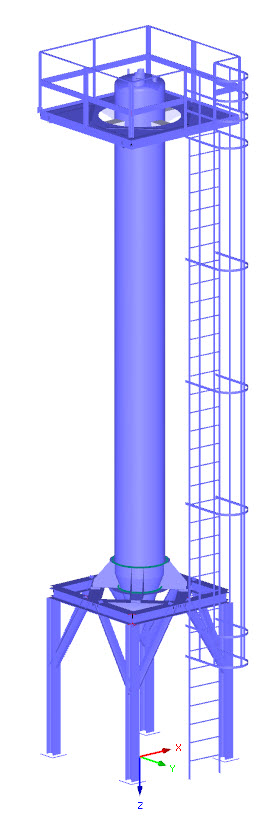

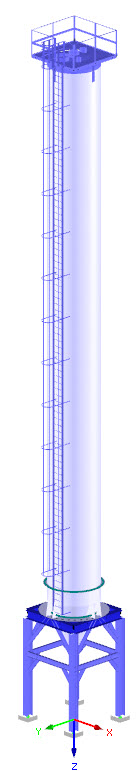

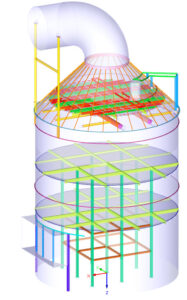

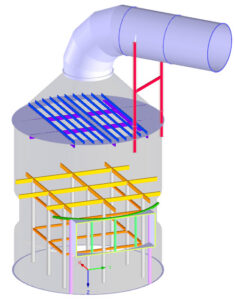

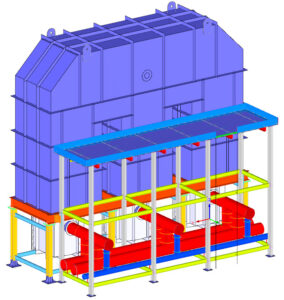

The reactors for PET processing are usually tall and slim constructions with a funnel in the lower part, which are mounted on a substructure and fixed to the foundation by means of anchor rods. Stress and stability proofs must be provided when dimensioning the reactor shell. Thereby the large pressure conditions are to be considered. The characteristic resistance values of the materials must be reduced according to the temperature. A special detail is the connection of the silo to the substructure. This can be solved by means of different constructions (clamps, stiffeners, support leg connection). Subsequently, locally high vertical acting forces and bending moments are introduced in a limited area. When connecting to constructions with smaller wall thicknesses or stiffnesses, it may be necessary to provide reinforcement plates to increase the effective width of the load introduction and to counteract local buckling or failure.

Energy stores

Energy storage systems play a key role today and in the future when it comes to the question of how to save energy (green energy) from renewable energy sources. The currently most frequently used energy stores are subdivided into the following groups, depending on the type of extraction:

- thermic energy

- mechanic energie

- chemical energie

- electrical energie

Many of the aforementioned energy sources are stored in tanks or containers. The excess energy generated from biomass, wind power, water power or solar energy, for example, is stored in tanks or containers.This is where a large part of the production process for storing the energy generated from renewable energy sources takes place. In addition to newly constructed pressure-shock-resistant tanks or vessels in segment design, existing oil or storage tanks can also serve as energy storage tanks if necessary.

Our services

The dimensioning for the tank structures is based on the Eurocodes as well as AD2000, DIN EN 14015 and DIN EN 13445. The following services for tank construction can be provided by SKI Ingenieurgesellschaft

- Static calculations for tanks and foundation slabs

- Foundations for battery storage systems

- Evidence and assessments concerning the increase of existing tanks

- Detailed evidence (e.g., for the manhole, lifting eyes, eye bars, pipe connections)

- Dynamic calculations (z.B. infolge eines Rührwerks, Wirbeleregte Querschwingungen, Galopping)

- Evidence for earthquake loads

- Numerical simulationsn (e.g. buckling stability under wind load, pressure conditions)

- Substructures (including connections)

- Anchorages in the foundation (anchor rods, claws, anchor plates, injection anchors)

- Reports in cases of damage and accidents

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0