A variety of roof constructions are available to close containers, silos or tanks upwards for various reasons. SKI Ingenieurges. mbH bietet die Möglichkeit im Bestand oder der Planung von Bauvorhaben eine Bemessung oder Begutachtung der verschiedensten Arten von Dachvarianten durchzuführen.

Roofs and covers

Covers of containers, silos and tanks

Tent roof (foil cover) with center support

The simplest form of tank cover is the tent roof or foil cover, which can be designed with or without a central support. The tent roof is stretched over the edge of the container with straps fastened to the central support. It reduces emissions (odour reduction) and prevents contamination of the storage liquid (e. g. leaves). In the case of a tent roof, the roof shape may not be dimensionally stable in extreme events, such as extreme snow or storm events.

Double membrane roof (wearing air) with/without central pillar

Double-membrane roofs, also known as air-supported roofs, are often used for fermentation residue storage tanks in biogas plants. A double membrane roof usually consists of two different membranes. The outer membrane is referred to as weather protection film and the inner membrane as gas storage film. The cavity between the two foils is pressurized by a backup air blower and keeps the roof in shape. Depending on the design of the support pressure, the double membrane roof may not remain dimensionally stable in extreme events such as extreme snow or storm events. First and foremost, a double membrane roof serves as weather protection or thermal insulation. There are versions with and without central support. In the case of double-diaphragm roofs with central supports, straps are tensioned radially between the central support and the container edge. This prevents the gas storage foil from depositing on the filling medium, e. g. in the state of maintenance.

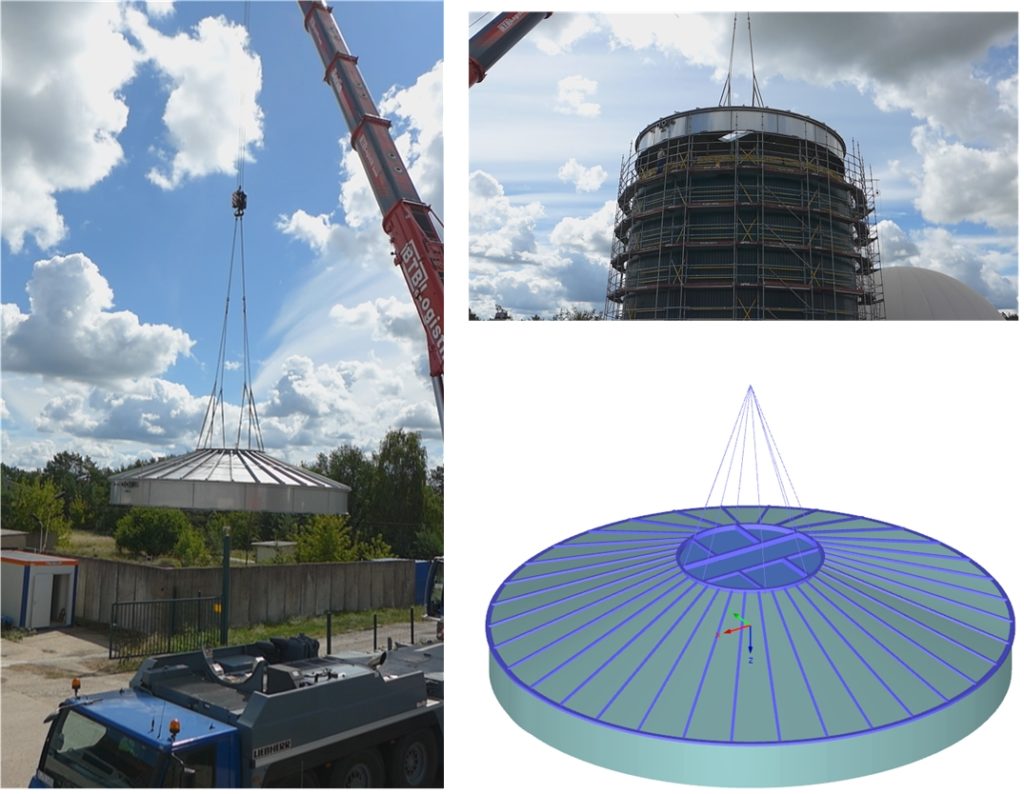

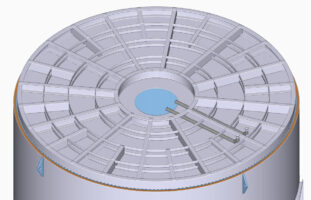

Rafter roof with crown ring

In the case of containers, tanks or silos with accessible roofs as well as higher loads due to pressure conditions, traffic loads and agitators, rafter roofs are generally used. In the centre of the roof is a crown ring, which serves as a connection for the rafters running to the edge of the vessel and for receiving an agitator. Rafters are self-supporting roofs and central supports, which transfer the roof loads via a shell support structure into the wall of the circular cylinder shell. These roofs are usually designed with a low roof pitch of < 20°.

Folded roof or flat roof

For smaller cylinder diameters, it is possible to form a rafter roof instead of a rafter roof. The rafters consisting of folded profiles (e. g. Z-profiles) are manufactured together with the roof cladding. The joints are then screwed together, which reduces the number of joints and fasteners compared to the rafter roof. Seam roofs are usually made of stainless steel.

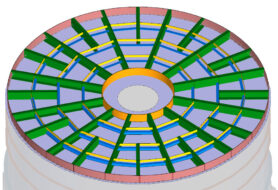

GfK segment roof

If a container cover with low dead weight and high resistance to chemically aggressive media is required, (glass) fibre-reinforced plastics are the material of choice. The roof shapes range from flat roofs to stiffened spherical shells and domes made of tonnage segments. The direction-dependent material properties for GfK roofs can be determined on the basis of DIN 18820 or the manufacturer's specifications.

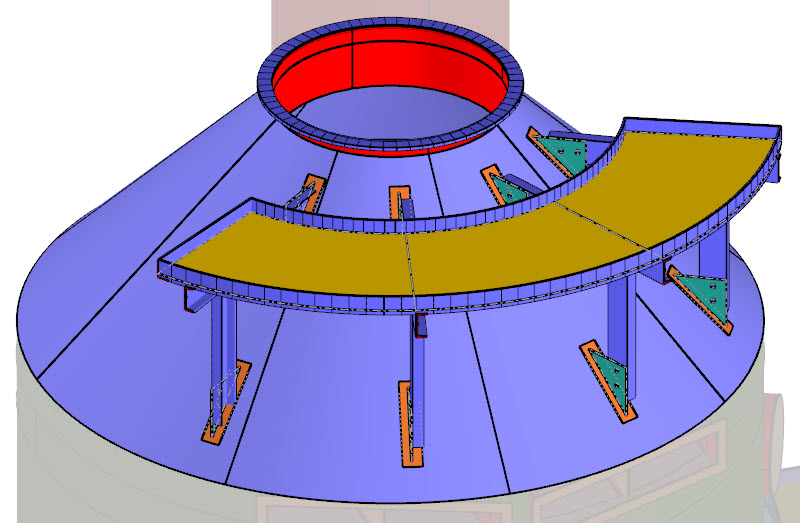

Cone and roof of frustum of cone

Cylindrical silos often end up with a bowl in the shape of a cone or truncated cone. For larger diameters, the roof segments are provided with a stiffening upstand in the radial direction or spherical roofs are constructed.

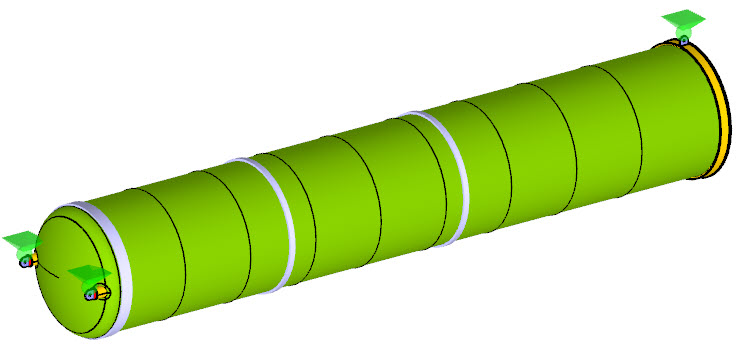

Thorispherical and spherical head

Als Korbbogen- oder Klöpperboden lassen sich die verschiedenen Böden zusammenfassen, die als Deckel von zylindrischen Druckbehältern oder anderen prozesstechnischen Behältern verwendet werden. Durch die abgeflachte “Halbkugelform” nehmen sie weniger Raum ein als die ideale Halbkugelform bei einer nur geringfügig dickeren Wandstärke. Genormt sind die Bezeichnungen Klöpperboden und Korbbogenboden mit den damit verbundenen Radienverhältnissen.

Calculation bases for the wall thickness calculation of dished heads under internal pressure loading are available in Germany in the relevant codes for the manufacture of pressure vessels according to the Pressure Equipment Directive AD 2000-Merkblatt as well as in the harmonized standard DIN EN 13445-3. Due to the internal pressure, the greatest stresses are in the area of the brim. For this reason, notches and other deformations should be avoided in this area and this area should usually be made thicker.

Services

SKI Ingenieurges. offers the following services within the scope of dimensioning and design of roofs or covers for containers, silos and tanks:

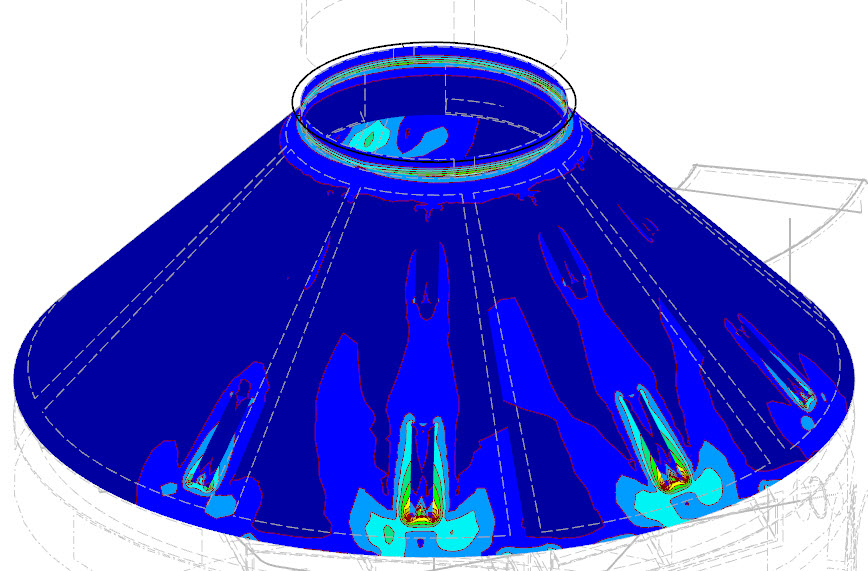

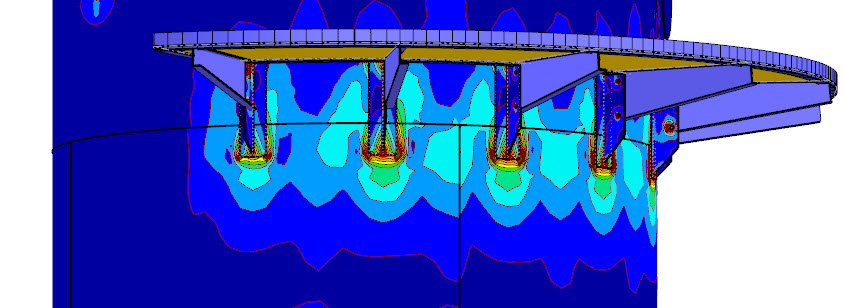

- Analytical or numerical calculations in the ultimate limit state and servicebilits limit state for all named types of roofs

- Checks by the membrane theory (flexural strength of the shell is very small)

- Determination of the branch oads

- Detail checks for bolted or welded connections

- Stability analsysis for roofs and covers

- Monitoring and evaluation of component tests

- Assessment of replacement or retrofitting of a tank covers

- Design taking into account the regulations for pressure equipment (AD 2000, EN 13445)

- Expert reports in case of damage to roofs or container covers

Copyright © 2026

SKI Ingenieurges. mbH

Mengendamm 12

30177 Hannover

Phone: +49 (0) 511 / 261847-0